The chemistry of explosives is a delicate matter. A little less carbon, a little more nitrogen, and the right amount of oxygen can transform a relatively inert substance into quite the showstopper.

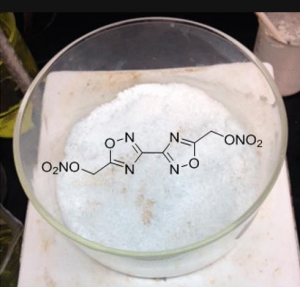

For more than 100 years, TNT has been the premier mixture of chemicals for blowing things up, and it’s even used as a metric to measure the yield of nuclear explosions and other monumental blasts. But new research out of Los Alamos National Laboratory and the Army Research Laboratory has discovered a new chemical, bis-oxadiazole (C6H4N6O8), that has many of the advantages of TNT, is thought to be less toxic to produce, and makes a bigger bang.

“It would be about 1.5 times the power of TNT,” says David Chavez, an explosives chemist at Los Alamos who worked on the new molecule. “So fairly energetic, quite a nice improvement compared to TNT.”

TNT, or trinitrotoluene, is a mixture of the seemingly innocent elements carbon, hydrogen, nitrogen, and oxygen (C7H5N3O6). Chavez compares such explosive compounds to gasoline, saying that rather than drawing oxygen from the air to serve as an oxidizer for combustion, like an engine does, the molecule simply has everything it needs for the combustive reaction stored within. And because everything is much more densely packed together in a TNT molecule than in the gas-air mixture that powers a car, the resulting explosion is orders of magnitude more powerful.

TNT also has a major advantage when it comes to manufacturing: it’s melt-castable. In other words, the melting point of TNT is low enough, about 80 degrees Celsius, that you can safely melt the material down into a liquid without it spontaneously detonating, which happens at about 240 degrees C. This allows manufacturers to pour liquid TNT into molds and shells to produce bombs.

“The place where you see it used most is mortar shells and artillery shells,” says Jesse Sabatini, a synthesis chemist with the Army Research Laboratory (ARL) at Aberdeen Proving Ground, Maryland.

But TNT has some major drawbacks that have led to a “quest to develop new melt-castable explosives,” says Sabatini, between the Department of Energy and the Department of Defense. TNT and other chemicals used in military explosives produce pollutants during manufacture, and they just aren’t as explosive as they could be.

“There is actually quite a bit of waste that’s generated by making TNT,” Chavez says. “There’s something that’s called red water, which is the kind of water that’s left over from the nitration of TNT. And then when the TNT itself is actually isolated, it’s washed with more water, and that water is a waste that’s called pink water, and it also has some environmental impacts.”

These pollutants can get into soil and water supplies, and TNT, due to its high vapor pressure, has a tendency to produce air pollutants that can harm workers melting down the material with steam. It’s also not that explosive, owing to the fact that TNT doesn’t have enough oxidizer to burn all its carbon and hydrogen fuel, which is why you see a black cloud of mostly carbon after TNT is detonated. So TNT is generally mixed with other chemicals, such as RDX to form an explosive mixture called Composition B that is found in many bombs. But RDX also produces pollutants that can seep into groundwater, and they don’t decompose easily.

“The Army always wants to have enhanced performance,” Sabatini says. “They want more blast. They want more power. And TNT is okay… but we want to do better than that.”

Searching for a substitute has been an ongoing effort spanning decades, and in 2016, ARL synthesized a compound with some promising results. Bis-isoxazole, as the compound is known, proved to be cleaner than TNT and melt-castable, but not as powerful. Working with Los Alamos, the Army set out to tweak the recipe.

Bis-isoxazole consists of two five-atom rings with three carbon atoms, one nitrogen, and one oxygen. By swapping out a carbon atom for another nitrogen, the chemists knew they would produce a compound with a higher explosive yield, though they did not know if it would be melt-castable. “There is really no way to predict melting point,” Sabatini says.

The result was the new molecule that could replace TNT, bis-oxadiazole. The additional nitrogen adds density to the molecule, and removing carbon helps balance out the oxidizer so all of the fuel can be used up to produce energy in the reaction. And once the researchers had synthesized it in the lab, they realized bis-oxadiazole has a melting point of around that of TNT, making it melt-castable.

“There was a little bit of luck sprinkled in there I suppose, but there really was a lot of chemical intuition that was involved,” Sabatini says.

There are two primary ways to measure the power of an explosion: detonation velocity and detonation pressure. According to chemical modeling, bis-oxadiazole should have a detonation velocity of around 8.18 km/s and detonation pressure of 29.4 gigapascal, compared to around 7.8 km/s and 26 gigapascal for Composition B. And from what the chemists know about the new material, any residue from manufacturing it should decompose much more easily in the environment.

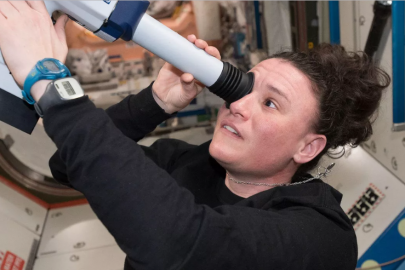

However, these specific points still need to be tested. In a recent study, the chemists demonstrated the ability to produce the new explosive on a scale of about 25 grams. The next steps are to scale that production up to hundreds of grams or pounds, Sabatini says, so that full toxicity screenings can be done as well as explosive tests in the field.

To measure the detonation velocity and pressure directly, Chavez says, the chemists make cylinders of the material and arrange them on a small steel block. A trigger on top of the setup blows the material, and sensors placed in between the cylinders are used to measure velocity, while the pressure can be calculated from the dent left in the steel.

Once toxicity and explosion tests are conducted, if the results are promising, the material will go through a whole new set of tests to incorporate it into something resembling an artillery shell. Then chemical manufacturing plants could begin the process of producing the material in large quantities.

Chavez says the average time from chemical discovery to manufacture of explosive devices is roughly 5 to 10 years. But if the new explosive material is as promising as it seems, and if the Pentagon decides that it has a need for new weapons sooner rather than later, you could possibly see bis-oxadiazole hit the battlefield even earlier.

“It is a compound that certainly has us excited,” Sabatini says.

Source: yahoo