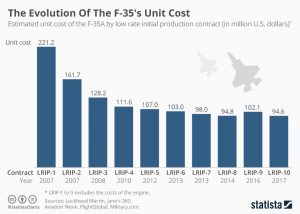

So far, the F-35 fighter jet is in Low Rate Initial Production or LRIP. In July, the Pentagon and Lockheed Martin reached a handshake deal for LRIP 11, or the eleventh production batch of F-35s – 141 jets in total for the U.S. and other customers. Although neither party divulged the total cost of the contract, Lockheed Martin is finally making progress in reducing the enormous cost per aircraft. When production started, the first two F-35As each had a unit cost of over $200 million.

When the F-35 moves from LRIP to full-rate production, costs are expected to be driven down by economies of scale with the manufacturer getting better deals for large shipments of parts and the provision of labor. That is expected to happen in three years with the U.S. military planning to transition from one-year block purchases to a longer-term multi-year procurement stategy. The acceleration in production is already yielding results with the Lot 10 contract seeing the aircraft’s unit price fall below $100 million for the first time. That is expected to fall even further to under $80 million by 2020.

The Lot 10 contract included 90 jets in total and represented a $728 million price reduction on LRIP-9. The following infographic shows how the cost of an F-35A fell 7.3 percent to $94.6 million. Even though the cost per unit is falling steadily, the U.S. and European customers still consider the jet’s operating cost a major problem. While the older F-16 averages $25,500 per flight hour, the brand new F-35 is averaging $30,000. Experts have said that unless maintenance and operating costs are reduced, the U.S. military may scale back its purchase of 1,763 F-35s. The total cost of the program over its 55-year lifespan is expected to be $1.5 trillion.

source: statista

Ask me anything

Explore related questions