Engineers at Sandia National Laboratories have developed what they say is the most durable metal alloy ever created. Made up of a combination of platinum and gold, the new material is apparently 100 times more wear-resistant than high-strength steel, which makes it the first metal alloy to join the same class as diamond. Even better, it naturally produces its own lubricant that, under normal circumstances, is extremely fiddly and expensive to make.

The Sandia alloy is made up of 90 percent platinum and 10 percent gold, and to illustrate how durable it is, the team uses a pretty colorful analogy. Imagine skidding on tires made of the new alloy – according to its inventors, only a single layer of atoms would be worn off after skidding for a mile, and you could drift around the Earth’s equator 500 times before the tread would give out.

Interestingly, this particular platinum-gold alloy isn’t new, but it had long been overlooked in terms of durability. That’s because when engineers are developing or studying tough alloys, they usually look to the harder ones. This alloy isn’t particularly hard, but was found to react to heat better, letting it resist damage from friction for longer.

“Many traditional alloys were developed to increase the strength of a material by reducing grain size,” says John Curry, first author of the study. “Even still, in the presence of extreme stresses and temperatures many alloys will coarsen or soften, especially under fatigue. We saw that with our platinum-gold alloy the mechanical and thermal stability is excellent, and we did not see much change to the microstructure over immensely long periods of cyclic stress during sliding.”

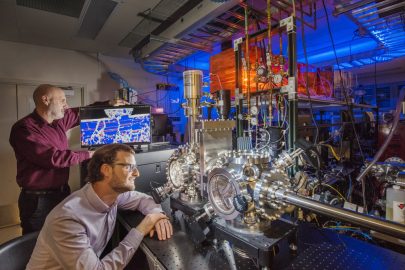

The researchers approached the problem using computer simulations to monitor what individual atoms were doing, and how that affected the overall properties of the material. From there, materials that have particularly desirable traits can be selected for further study, combined and eventually tested in the real world.

“We’re getting down to fundamental atomic mechanisms and microstructure and tying all these things together to understand why you get good performance or why you get bad performance, and then engineering an alloy that gives you good performance,” says Michael Chandross, co-author of the study.

But there’s an even weirder wrinkle to the story. During testing, the researchers realized that a black film had started forming on top of the alloy. This stuff turned out to be diamond-like carbon, an effective lubricant that normally takes a pretty involved and expensive process to create.

“We believe the stability and inherent resistance to wear allows carbon-containing molecules from the environment to stick and degrade during sliding to ultimately form diamond-like carbon,” says Curry. “Industry has other methods of doing this, but they typically involve vacuum chambers with high temperature plasmas of carbon species. It can get very expensive.”

Not only could this spontaneous production of lubricant help the alloy last even longer, but it could be harnessed as a new, easier way to mass produce diamond-like carbon for other industrial uses.

The research was published in two papers, one appearing in Advanced Materials and the other in the journal Carbon.

Source: newatlas

Ask me anything

Explore related questions